AI for Supply Chain Optimization: 2025 Cost Reduction Guide

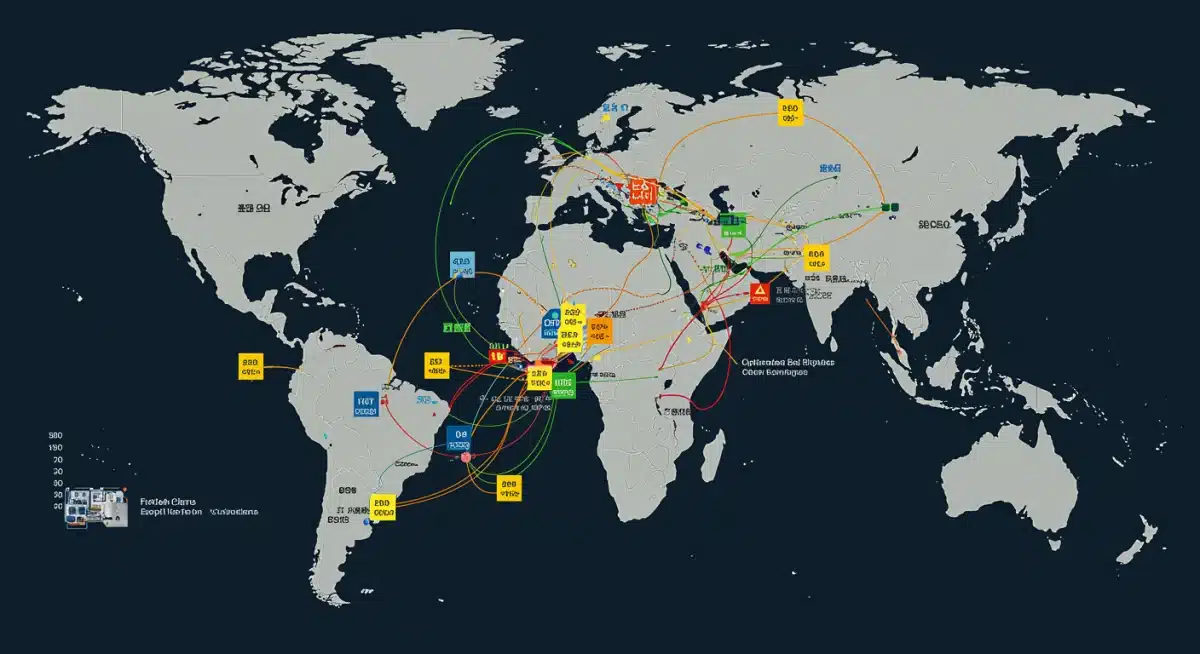

Leveraging AI for supply chain optimization: A 2025 Guide to Reducing Operational Costs by 15% details how artificial intelligence is fundamentally transforming logistics and procurement, enabling businesses to achieve substantial cost savings and enhanced efficiency through advanced data analysis and automation.

The imperative for businesses to enhance efficiency and reduce expenditures has never been more critical. As we approach 2025, the strategic implementation of Leveraging AI for Supply Chain Optimization: A 2025 Guide to Reducing Operational Costs by 15% is emerging as a cornerstone for achieving these ambitious targets. This guide explores how AI is reshaping traditional supply chain paradigms, offering unprecedented opportunities for cost reduction and operational excellence.

The AI Revolution in Supply Chain: A New Era of Efficiency

Artificial Intelligence (AI) is no longer a futuristic concept but a present-day reality profoundly impacting supply chain management. Companies are now actively integrating AI to tackle complex challenges, from unpredictable demand fluctuations to global logistical disruptions. This shift is not merely about automation; it’s about intelligent decision-making at every stage.

Recent reports from industry leaders and technology analysts, including a prominent whitepaper released by Accenture on November 15, 2024, highlight that early adopters of AI in supply chains are already reporting significant gains. These gains are primarily seen in areas like inventory management and logistics planning, setting a strong precedent for broader adoption. The expectation is that by 2025, AI will be a standard component in competitive supply chain strategies.

Predictive Analytics: Forecasting the Future of Demand

One of AI’s most powerful applications in the supply chain is its capability for predictive analytics. By analyzing vast datasets, AI algorithms can forecast demand with remarkable accuracy, far surpassing traditional statistical methods. This allows businesses to optimize inventory levels, reducing carrying costs and minimizing stockouts.

- Enhanced Accuracy: AI models learn from historical sales, market trends, and even external factors like weather patterns or social media sentiment to provide highly accurate demand forecasts.

- Reduced Inventory Costs: Precise forecasting means fewer excess goods, leading to lower storage, insurance, and obsolescence costs.

- Improved Customer Satisfaction: Meeting customer demand consistently enhances brand loyalty and reduces lost sales opportunities.

Automating Operations for Unprecedented Cost Savings

Automation, powered by AI, is transforming routine and complex tasks across the supply chain. From automated warehousing to intelligent route optimization, these technologies are driving down labor costs, increasing speed, and reducing errors. The push towards greater automation is a key driver for achieving the 15% operational cost reduction target by 2025.

Consider the advancements in robotic process automation (RPA) and autonomous mobile robots (AMRs). These systems are streamlining warehouse operations, handling tasks such as picking, packing, and sorting with minimal human intervention. This not only cuts down on manual labor expenses but also boosts throughput and operational consistency, as observed in recent implementations by major e-commerce platforms.

Intelligent Logistics and Route Optimization

AI algorithms are revolutionizing logistics by optimizing delivery routes in real-time, considering traffic, weather, and delivery schedules. This leads to significant fuel savings, reduced vehicle wear and tear, and faster delivery times. Such efficiency directly translates into lower operational costs.

- Dynamic Route Planning: AI continuously adjusts routes based on live data, avoiding delays and maximizing delivery efficiency.

- Fleet Management: AI monitors vehicle performance and maintenance needs, preventing costly breakdowns and extending asset lifespan.

- Last-Mile Delivery Optimization: Especially critical in urban areas, AI helps coordinate complex last-mile deliveries, reducing overall transportation expenses.

Real-Time Insights and Data-Driven Decision Making

The ability of AI to process and analyze massive amounts of data in real-time provides unprecedented insights into supply chain performance. This data-driven approach empowers managers to make informed decisions quickly, mitigating risks and capitalizing on opportunities. This agility is crucial in today’s fast-paced global market, directly contributing to cost efficiency.

AI platforms can integrate data from various sources, including IoT devices, ERP systems, and external market data. This holistic view allows for continuous monitoring of key performance indicators (KPIs) and immediate identification of anomalies or potential disruptions. For instance, a sudden spike in a raw material price can be flagged instantly, allowing procurement teams to adjust strategies proactively.

The continuous feedback loop provided by AI systems means organizations can adapt their strategies with greater precision. This iterative improvement process is vital for sustained cost reduction. As reported by Gartner on November 20, 2024, companies leveraging real-time AI insights are outperforming their peers in terms of both operational efficiency and market responsiveness.

Enhancing Supply Chain Resilience with AI

Beyond cost reduction, AI plays a critical role in building more resilient supply chains. By identifying potential risks before they escalate, AI systems can help businesses navigate disruptions, from natural disasters to geopolitical events. This proactive risk management minimizes financial losses associated with unforeseen interruptions.

AI can simulate various scenarios, allowing companies to stress-test their supply chains and develop contingency plans. This foresight is invaluable in a world where supply chain vulnerabilities have been repeatedly exposed. For example, AI can analyze supplier performance and geopolitical stability to recommend alternative sourcing options, ensuring continuity of supply.

Proactive Risk Management and Anomaly Detection

AI-powered anomaly detection systems continuously scan for unusual patterns in data that might indicate a budding problem. This could be anything from a sudden drop in a supplier’s delivery performance to an unexpected surge in returns. Early detection allows for swift intervention, preventing minor issues from becoming major crises.

- Supplier Risk Assessment: AI evaluates supplier reliability, financial stability, and compliance, enabling more informed partnership decisions.

- Disruption Forecasting: Algorithms analyze global events and historical data to predict potential disruptions, allowing for pre-emptive action.

- Inventory Buffering: AI helps determine optimal safety stock levels for critical components, balancing cost against risk of stockouts during disruptions.

Overcoming Implementation Challenges for Maximum ROI

Implementing AI in supply chain operations is not without its challenges. Data quality, integration with existing systems, and the need for specialized talent are significant hurdles. However, the potential returns on investment (ROI) far outweigh these initial obstacles, especially when considering the 15% operational cost reduction target for 2025.

Companies must invest in robust data governance strategies to ensure the accuracy and reliability of the data fed into AI models. Without clean, consistent data, AI’s effectiveness is significantly diminished. Furthermore, seamless integration with legacy systems is crucial to avoid creating data silos and to ensure a unified operational view. Building an AI-ready infrastructure is a foundational step.

Strategic Partnerships and Talent Development

Addressing the talent gap is another critical component. Businesses often need to either upskill their existing workforce or recruit specialists in AI, data science, and machine learning. Collaborating with technology providers and academic institutions can also accelerate AI adoption and ensure access to cutting-edge solutions.

- Data Governance: Establishing clear policies and procedures for data collection, storage, and usage is paramount.

- System Integration: Developing APIs and middleware to connect AI platforms with existing ERP, WMS, and TMS systems is essential.

- Workforce Training: Investing in training programs to equip employees with the skills needed to manage and leverage AI tools.

The Future of Supply Chain: AI-Driven and Hyper-Connected

Looking towards 2025 and beyond, AI will continue to be a transformative force in supply chain management. The evolution of AI will lead to more sophisticated autonomous systems, hyper-personalized logistics, and even predictive maintenance for infrastructure. The goal of a 15% operational cost reduction is just the beginning; the long-term benefits are expected to be far more extensive, creating truly intelligent and self-optimizing supply chains.

The integration of AI with other emerging technologies, such as blockchain for enhanced traceability and IoT for real-time asset tracking, will create a hyper-connected ecosystem. This synergy will unlock new levels of transparency, security, and efficiency. The supply chain of the future will be a dynamic, self-learning network capable of adapting to change and optimizing itself autonomously, delivering unprecedented value.

As the competitive landscape intensifies, companies that embrace AI now will be better positioned to thrive. The journey to an AI-optimized supply chain is continuous, requiring ongoing investment in technology, talent, and strategic vision. The rewards, however, in terms of reduced costs, increased resilience, and superior customer experiences, are substantial and undeniable.

| Key Point | Brief Description |

|---|---|

| Predictive Analytics | AI forecasts demand, optimizing inventory and reducing carrying costs significantly. |

| Operational Automation | AI-powered robots and RPA streamline warehousing and logistics, cutting labor and errors. |

| Real-Time Insights | AI provides immediate data analysis for agile decision-making and risk mitigation. |

| Supply Chain Resilience | AI identifies and mitigates potential disruptions, ensuring business continuity. |

Frequently Asked Questions About AI in Supply Chain

AI reduces costs by optimizing inventory through predictive analytics, automating repetitive tasks, streamlining logistics with intelligent routing, and providing real-time insights for efficient decision-making, targeting a 15% reduction by 2025.

Key benefits include enhanced demand forecasting, significant cost savings in logistics and warehousing, improved operational efficiency, increased supply chain resilience against disruptions, and better customer satisfaction through consistent product availability.

Challenges include ensuring high data quality, integrating AI systems with existing legacy infrastructure, and addressing the talent gap by either upskilling current employees or recruiting specialized AI and data science professionals to manage new technologies.

AI enhances resilience by proactively identifying potential risks, simulating disruption scenarios, and recommending alternative strategies like diversified sourcing. It also uses anomaly detection to flag issues early, minimizing their impact on operations and continuity.

By 2025, AI is expected to be a standard component in competitive supply chain strategies, driving significant operational cost reductions. It will enable more sophisticated autonomous systems, hyper-personalized logistics, and predictive maintenance across the entire network.

Looking Ahead: The Evolving Landscape of AI in Supply Chains

The journey towards fully AI-optimized supply chains is dynamic and ongoing. As we move closer to 2025, the focus will intensify on integrating AI more deeply across all operational facets, aiming to exceed the 15% cost reduction target. Expect to see continuous advancements in AI’s ability to handle increasingly complex global logistics, predict market shifts with greater precision, and adapt to unforeseen events with minimal human intervention. The next phase will also involve tighter integration with blockchain and IoT, creating a truly transparent and self-managing supply ecosystem, driving efficiency and resilience to new heights.